Boosting Productivity and Safety: The Advantages of Using Nylon Strip Brushes in Conveyor Systems

Aug 21, 2023

Boosting Productivity and Safety: The Advantages of Using Nylon Strip Brushes in Conveyor Systems

Aug 21, 2023

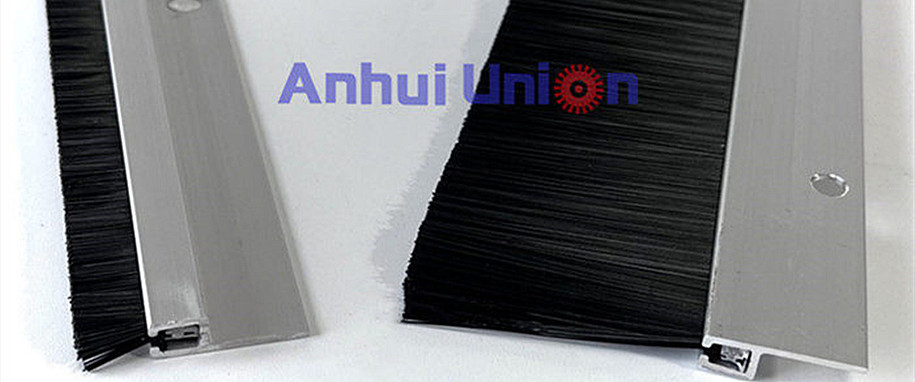

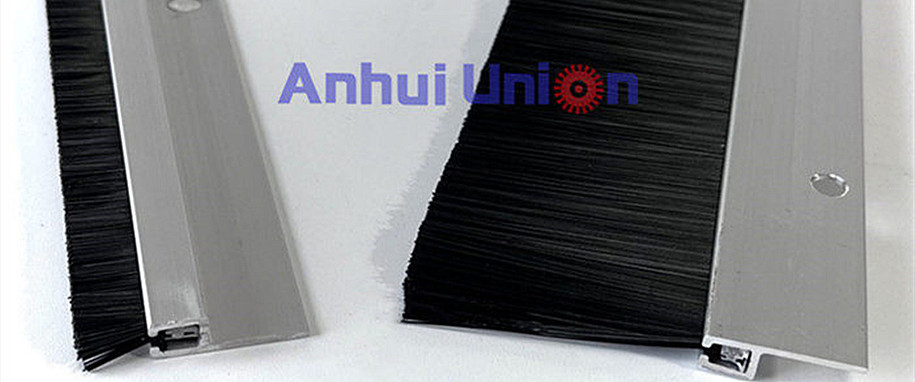

Enhance your productivity and ensure safety in your conveyor systems with the use of nylon strip brushes. These versatile brushes offer a multitude of advantages, making them an essential component for any industry that relies on conveyor systems to transport goods.

With their durable nylon bristles, these brushes effectively clean and condition conveyor belts, preventing the accumulation of debris and improving overall system efficiency. This not only minimizes downtime for maintenance and cleaning but also extends the lifespan of your conveyor system, saving you valuable time and money in the long run.

Nylon strip brushes also play a crucial role in enhancing workplace safety. By eliminating the build-up of dirt, dust, and contaminants on conveyor belts, they help reduce the risk of slips, trips, and falls. Additionally, these brushes act as a barrier, preventing unwanted objects from falling between the conveyor belts and causing damage or compromising the integrity of the system.

Investing in nylon strip brushes for your conveyor systems is a smart choice that will bolster productivity, prolong system lifespan, and ensure a safer work environment. Upgrade your operations today and reap the benefits of this simple yet powerful solution.

How nylon strip brushes enhance productivity in conveyor systems

Nylon bristle strip is designed to effectively clean and condition conveyor belts, preventing the accumulation of debris and improving overall system efficiency. With their durable nylon bristles, these brushes are able to withstand the rigors of continuous use, ensuring optimal performance.

One of the key benefits of using nylon strip brushes is their ability to minimize downtime for maintenance and cleaning. By effectively removing dirt, dust, and other particles from the conveyor belts, these brushes reduce the need for frequent manual cleaning, allowing your system to operate at maximum capacity for longer periods of time.

Additionally, the use of nylon strip brushes extends the lifespan of your conveyor system. By preventing the build-up of debris, these brushes help to reduce wear and tear on the belts, rollers, and other components, resulting in fewer repairs and replacements. This not only saves you valuable time and money but also improves the overall efficiency of your operations.

The safety benefits of using nylon strip brushes in conveyor systems

Safety is a top priority in any workplace, and conveyor systems are no exception. Nylon strip brushes play a crucial role in enhancing workplace safety by eliminating the build-up of dirt, dust, and contaminants on conveyor belts.

By effectively cleaning the belts, nylon strip brushes help to reduce the risk of slips, trips, and falls in the workplace. The accumulation of debris on conveyor belts can create a hazardous environment, especially in areas where employees are required to walk or stand near the system. With nylon strip brushes in place, the risk of accidents caused by slippery belts is significantly reduced.

Furthermore, nylon strip brushes act as a barrier, preventing unwanted objects from falling between the conveyor belts and causing damage or compromising the integrity of the system. This not only protects the equipment but also ensures the safety of employees working in close proximity to the conveyor system.

Frequently asked questions about nylon strip brushes in conveyor systems

1. Q: Can nylon strip brushes be used on all types of conveyor belts?

A: Yes, nylon strip brushes can be used on a wide range of conveyor belts, including PVC, rubber, and modular plastic belts. However, it is important to ensure compatibility between the brush and the belt material to avoid any potential damage.

2. Q: Are nylon strip brushes suitable for food processing applications?

A: Yes, nylon strip brushes are commonly used in food processing applications. They are designed to effectively remove food particles and contaminants from conveyor belts, ensuring compliance with food safety regulations.

3. Q: How often should nylon strip brushes be replaced?

A: The lifespan of nylon strip brushes can vary depending on factors such as usage, operating conditions, and maintenance. Regular inspections should be conducted to identify brushes that show signs of wear, damage, or bristle loss. These brushes should be promptly replaced to maintain optimal performance.

4. Q: Can nylon strip brushes be customized to fit specific conveyor system requirements?

A: Yes, nylon strip brushes can be customized to fit specific conveyor system requirements. Brush suppliers and manufacturers can provide tailored solutions based on factors such as belt width, material, and cleaning requirements.

5. Q: Are nylon strip brushes easy to clean?

A: Yes, nylon strip brushes are relatively easy to clean. Regular cleaning with a brush cleaner or a mild detergent solution, followed by thorough rinsing with clean water, is usually sufficient to maintain their cleaning efficiency.

By addressing these frequently asked questions, we hope to provide clarity and additional information about the use of nylon strip brushes in conveyor systems.

Boosting Productivity and Safety: The Advantages of Using Nylon Strip Brushes in Conveyor Systems

Aug 21, 2023

Boosting Productivity and Safety: The Advantages of Using Nylon Strip Brushes in Conveyor Systems

Aug 21, 2023