Maximizing Productivity and Minimizing Downtime: How a Conveyor Belt Brush Cleaner Can Help

Jun 27, 2023

Maximizing Productivity and Minimizing Downtime: How a Conveyor Belt Brush Cleaner Can Help

Jun 27, 2023

In today's fast-paced world, maximizing productivity and minimizing downtime is a top priority for businesses across various industries. One often overlooked but crucial aspect of this equation is the cleanliness and efficiency of conveyor belt systems. A conveyor belt brush cleaner is a simple yet highly effective solution that can make a significant difference in optimizing operations. By removing debris, dust, and other contaminants, it ensures smooth and uninterrupted movement of materials, preventing costly breakdowns and delays. But its benefits go beyond just maintenance. With a cleaner conveyor belt, businesses can enhance product quality, reduce wear and tear on equipment, and improve overall workplace safety. In this article, we will explore the various advantages of a conveyor belt brush cleaner and how it can revolutionize your operations, helping you achieve maximum productivity while minimizing downtime.

The importance of productivity and minimizing downtime in manufacturing

In the competitive landscape of manufacturing, maximizing productivity is crucial for businesses to stay ahead. Every minute of downtime can result in lost revenue, missed deadlines, and dissatisfied customers. To ensure smooth operations and meet production targets, minimizing downtime is of utmost importance. However, achieving high productivity and minimizing downtime is easier said than done. There are several challenges that businesses face, especially when it comes to conveyor belt systems.

Common challenges that hinder productivity in conveyor belt systems

Conveyor belt systems are widely used in various industries to transport materials efficiently. However, they are susceptible to several challenges that can hinder productivity. One common challenge is the accumulation of debris and contaminants on the conveyor belt. Over time, dust, dirt, and other particles can accumulate, leading to belt slippage, increased friction, and reduced efficiency. This not only slows down the movement of materials but also puts unnecessary strain on the equipment.

Another challenge is the potential for material spillage or product loss. When materials are not properly contained on the conveyor belt, they can spill over, leading to wastage and increased cleanup time. This not only affects productivity but also poses safety risks for workers who may need to clean up the spillage.

Furthermore, the buildup of debris on the conveyor belt can lead to increased maintenance requirements. As the belt becomes dirty, it becomes more prone to wear and tear, requiring frequent repairs or replacement. This not only adds to the downtime but also increases operational costs.

How conveyor belt brush cleaners work

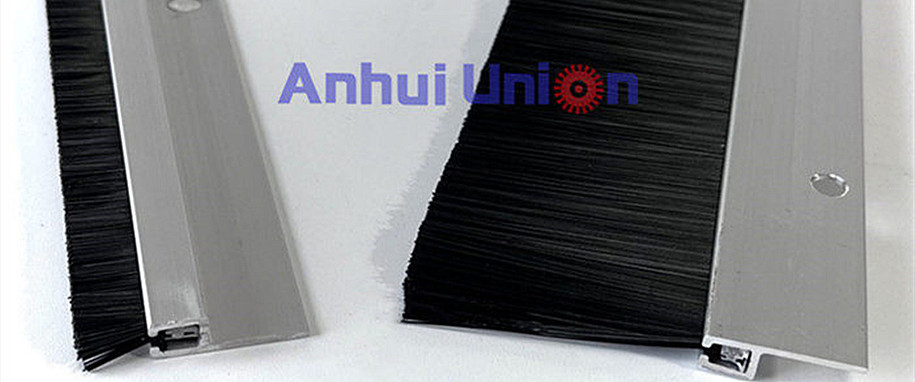

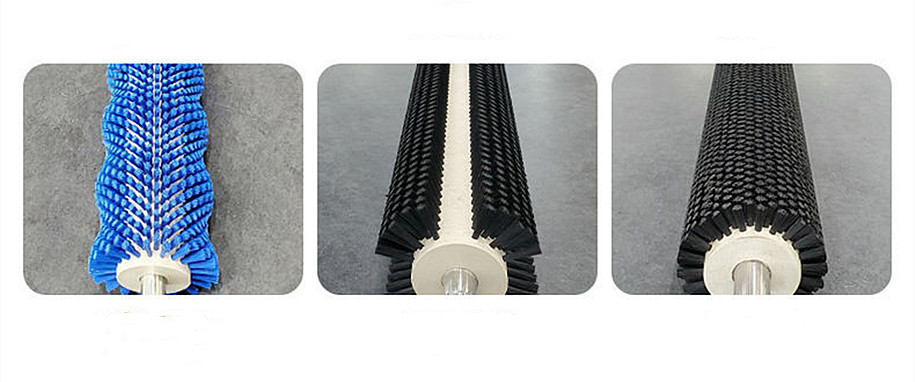

A conveyor belt brush cleaner is a simple yet effective device that can address these challenges and improve productivity in conveyor belt systems. It consists of a brush assembly that is mounted on the conveyor system, typically at the head pulley. As the conveyor belt moves, the brush assembly comes into contact with the belt surface, effectively brushing off any debris or contaminants.

The brush assembly is designed to have optimal contact with the belt, ensuring thorough cleaning without causing any damage. The bristles of the brush are usually made of durable materials such as nylon or polypropylene, which are effective at removing debris while being gentle on the belt surface.

The design of the brush cleaner allows for easy installation and maintenance. It can be easily mounted on the conveyor system using brackets or clamps, and the brush assembly can be adjusted to achieve the desired contact pressure. Regular cleaning and maintenance of the brush cleaner are simple tasks that can be incorporated into the routine maintenance schedule of the conveyor system.

Key features to consider when choosing a conveyor belt brush cleaner

When selecting a conveyor belt brush cleaner for your operations, there are several key features to consider. Firstly, the brush cleaner should be compatible with your specific conveyor system. It should be able to fit seamlessly into the existing system without requiring major modifications.

Secondly, the brush cleaner should have adjustable settings to accommodate different belt widths and materials. This ensures that the brush assembly can be properly aligned with the belt surface, maximizing cleaning efficiency.

Another important feature to consider is the durability of the brush cleaner. It should be able to withstand the rigors of continuous operation and resist wear and tear. Look for brush cleaners that are made of high-quality materials and have a proven track record of performance and longevity.

Furthermore, consider the ease of installation and maintenance. A brush cleaner that is easy to install and maintain will save valuable time and resources. Look for brush cleaners that come with clear installation instructions and require minimal effort to clean and maintain.

Case studies: Real-world examples of improved productivity with conveyor belt brush cleaners

To illustrate the impact of conveyor belt brush cleaners on productivity and downtime reduction, let's look at some real-world case studies.

Case Study 1: Manufacturing Plant

A manufacturing plant that produces automotive components was experiencing frequent breakdowns and delays due to debris accumulation on their conveyor belts. This not only disrupted their production schedule but also resulted in increased maintenance costs. After implementing conveyor belt brush cleaners, they noticed a significant improvement in productivity. The brush cleaners effectively removed debris, ensuring smooth movement of materials. As a result, the plant was able to meet production targets consistently, reduce equipment maintenance requirements, and minimize downtime.

Case Study 2: Food Processing Facility

A food processing facility was facing challenges with material spillage and contamination on their conveyor belts. This posed a risk to product quality and worker safety. By installing conveyor belt brush cleaners, they were able to maintain a clean and safe working environment. The brush cleaners effectively removed spillage and contaminants, reducing the risk of product contamination and minimizing cleanup time. As a result, the facility saw an increase in productivity, improved product quality, and enhanced workplace safety.

Installation and maintenance tips for conveyor belt brush cleaners

Proper installation and maintenance are crucial for the effective performance of conveyor belt brush cleaners. Follow these tips to ensure optimal results:

1. Choose the right brush cleaner: Select a brush cleaner that is suitable for your specific conveyor system and material handling requirements.

2. Ensure proper alignment: Align the brush assembly with the belt surface to ensure optimal contact and cleaning efficiency. Adjust the brush cleaner as needed to accommodate different belt widths and materials.

3. Regular cleaning: Incorporate regular cleaning of the brush assembly into your routine maintenance schedule. Remove any accumulated debris or contaminants to maintain optimal performance.

4. Inspect for wear and tear: Regularly inspect the brush cleaner for any signs of wear and tear. Replace worn-out bristles or damaged components to ensure continued effectiveness.

5. Train your maintenance staff: Provide proper training to your maintenance staff on the installation, adjustment, and cleaning procedures for the conveyor belt brush cleaner. This will ensure that they can perform these tasks effectively and efficiently.

Other solutions for maximizing productivity in conveyor belt systems

While conveyor belt brush cleaners are highly effective in improving productivity, there are other solutions that can further enhance efficiency in conveyor belt systems. Consider implementing the following:

1. Proper belt tracking: Ensure that the conveyor belt is properly aligned and tracked to prevent unnecessary friction and wear. Use tracking devices or sensors to monitor and adjust belt alignment as needed.

2. Effective material containment: Install skirt boards or sealing systems to prevent material spillage and loss. This will not only improve productivity but also reduce cleanup time and minimize product wastage.

3. Routine maintenance and inspections: Regularly inspect and maintain the entire conveyor system to identify and address any potential issues before they escalate. This includes checking for worn-out components, loose bolts or fasteners, and lubricating moving parts.

4. Effective training and communication: Provide comprehensive training to your employees on proper conveyor system operation, maintenance, and safety protocols. Ensure clear communication channels so that any issues or concerns can be addressed promptly.

The cost-effectiveness of conveyor belt brush cleaners

When considering the investment in a conveyor belt brush cleaner, it is important to evaluate the cost-effectiveness of the solution. While the initial cost may vary depending on the specific requirements of your conveyor system, the long-term benefits far outweigh the investment.

By minimizing downtime and reducing equipment maintenance requirements, conveyor belt brush cleaners can significantly improve productivity and operational efficiency. This translates into cost savings and increased profitability in the long run. Additionally, the enhanced product quality and workplace safety contribute to customer satisfaction and employee morale, further adding value to your business.

Conclusion: The impact of a conveyor belt brush cleaner on productivity and downtime reduction

In conclusion, a conveyor belt brush cleaner is a valuable tool for maximizing productivity and minimizing downtime in conveyor belt systems. By effectively removing debris, dust, and contaminants, it ensures smooth and uninterrupted movement of materials, reducing breakdowns and delays. With cleaner conveyor belts, businesses can achieve higher productivity, improved product quality, reduced equipment maintenance, and enhanced workplace safety.

When selecting a conveyor belt brush cleaner, consider key features such as compatibility, adjustability, durability, and ease of installation and maintenance. Real-world case studies demonstrate the positive impact of brush cleaners on productivity and downtime reduction.

Incorporate proper installation and maintenance practices to ensure optimal performance of conveyor belt brush cleaners. Additionally, consider other solutions such as proper belt tracking, material containment, routine maintenance, and effective training to further maximize productivity in conveyor belt systems.

While there is an initial investment involved, the cost-effectiveness of conveyor belt brush cleaners is evident in the long-term benefits they provide. By investing in a conveyor belt brush cleaner, businesses can revolutionize their operations, achieve maximum productivity, and minimize downtime, ultimately leading to increased profitability and success.

What Is Cylindrical Roller Brush

Jun 16, 2023

What Is Cylindrical Roller Brush

Jun 16, 2023

Maximizing Productivity and Minimizing Downtime: How a Conveyor Belt Brush Cleaner Can Help

Jun 27, 2023

Maximizing Productivity and Minimizing Downtime: How a Conveyor Belt Brush Cleaner Can Help

Jun 27, 2023

Cylindrical Nylon Brush: A Versatile Cleaning Tool for Various Surfaces

Jul 25, 2023

Cylindrical Nylon Brush: A Versatile Cleaning Tool for Various Surfaces

Jul 25, 2023

Boosting Productivity and Safety: The Advantages of Using Nylon Strip Brushes in Conveyor Systems

Aug 21, 2023

Boosting Productivity and Safety: The Advantages of Using Nylon Strip Brushes in Conveyor Systems

Aug 21, 2023

All You Need to Know About Cylinder Brushes: A Comprehensive Guide

Aug 26, 2023

All You Need to Know About Cylinder Brushes: A Comprehensive Guide

Aug 26, 2023

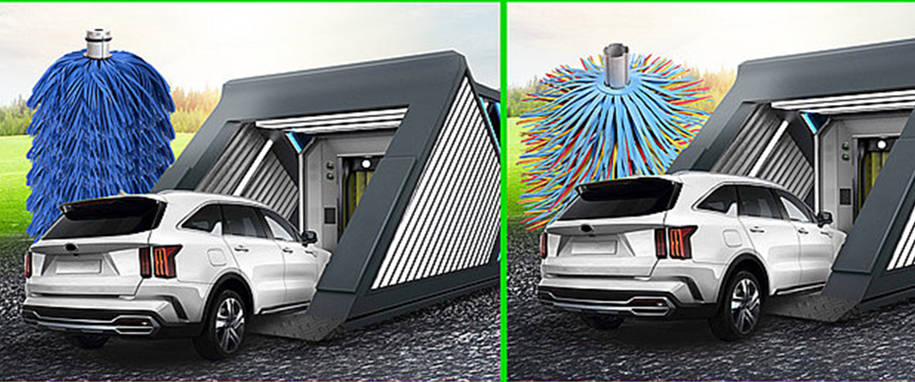

The Untold Benefits of the EVA Foam Brush for Car Wash

Nov 02, 2023

The Untold Benefits of the EVA Foam Brush for Car Wash

Nov 02, 2023